Automation for Soldermask DRS-L

Highlights

- With a cycle time of 13 sec for the models DRS and DRI incl. 3 sec table change time, capacities of > 2 PCB/min – processed on both sides – are possible

- Prepared for MES (OPC/UA) connection

- Handling up to 6kg PCBs

- 100% traceability via logfile & database

- Contact-free centering via CCD cameras (very high positioning accuracy)

- No scratching of the PCB surface

- Variable offsets (X, Y & R axis) can be set for all robot positions (pick & place) in automatic mode

- Placing position on LDI / AOI table can be confi gured by +/- 90 ° or 180 ° turning (may lead to cycle time savings for the process machine)

- The automation reacts status-oriented. Example: If a PCB is lost or an LDI/AOI malfunctions with subsequent inital reset, the automation automatically recognizes the new situation. Production can continue seamlessly

- Logfile creation: Alarm history, Event, Interface M2M

- Offset placing of OK boards individually adjustable via HMI

- Simple manual intervention, without interruption of the running automatic mode

- Database connection (read & write) *

- Automatic gripper adjustment incl. format check without cycle time loss

- Order data collection via DMC * on the PCB or via job list

- Automatic Dummy Recognition (job separator) *

- Certifi ed ESD version *

- Control of processes via weight and thickness information *

- Automatic cleaning of each side before processing via non-contact cleaning systems*

- Automatic override setting according to PCBs weight (process safety)

Description

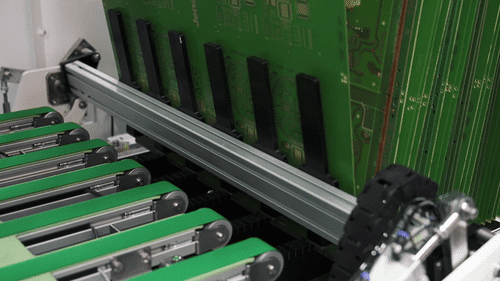

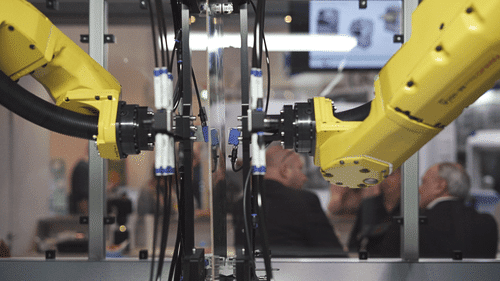

The PCBs are handled by 6-axis robot 1 from an inclined cassette or a slot cassette to the contact-free camera adjustment. Accurate, if necessary touching only in the edge area, they are placed on the process machine via a reliable gripper system with individual ejectors for each suction cup. After processing the first side the flipping is done by transferring the board from robot 2 back to robot 1. The fi nished processed PCB is then stored by the second robot on an L-rack or in a slot cassette. In principle automation acts as the master for the process machine. Order data are transfered for each individual PCB to the process machine from the PCB coding or by input into the HMI – manually or via bar code readers. This speeds up the data preparation and the automation can automatically adapt to the different board conditions (size, weight, order change) if necessary. The system can be executed optionally with a cassette for NOKPCBs and with slip-sheet handling.

Klicken Sie auf den unteren Button, um den Inhalt von customer-181znpukyiq9repm.cloudflarestream.com zu laden.