Robocut RC2

Highlights

- Up to 2,640 printed circuit boards / 22-hours operation

- For Masslam and Pinlam

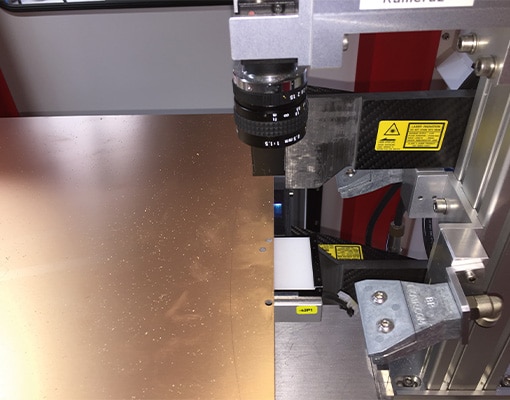

- PCB alignment via high-resolution CCD camera with PCB twist detection

- PCB thickness measurement with a resolution of 0.2 microns

- Optional: Free milling station for registration holes

- Optional: Intermediate layer handling

- Optional: integrated dry cleaning

- Optional: Integrated -Inline Multi-thickness measurement (single-lane alternatively multi-lane)

- Automatic production data collection and evaluation

Description

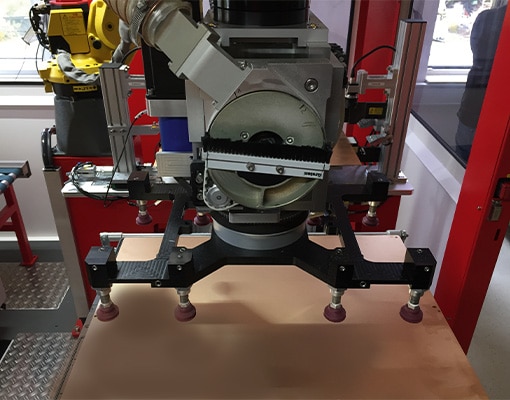

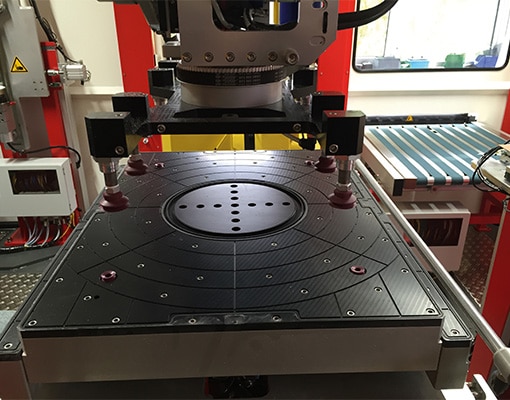

Masslam and Pinlam Multilayers are fed to the Robocut inline or via angle of inclination cassettes, horizontal boxes or pallets. Alignment is done via high-resolution CCD cameras. Using two 6-axis robots, the printed circuit boards are first fed to the high-performance impact scissors after alignment in order to cut the edges. The waste is collected in an easy-to-use way via an integrated and movable waste container. On a vacuum table with different vacuum zones for the different PCB formats, the edges are lined and the corners are rounded. Optionally, in Pinlam applications, the registration holes can be milled from above and below from the resin flow at a separate station. The production programs can be read via barcode, QR code, drilling code or order lists.

Klicken Sie auf den unteren Button, um den Inhalt von customer-181znpukyiq9repm.cloudflarestream.com zu laden.