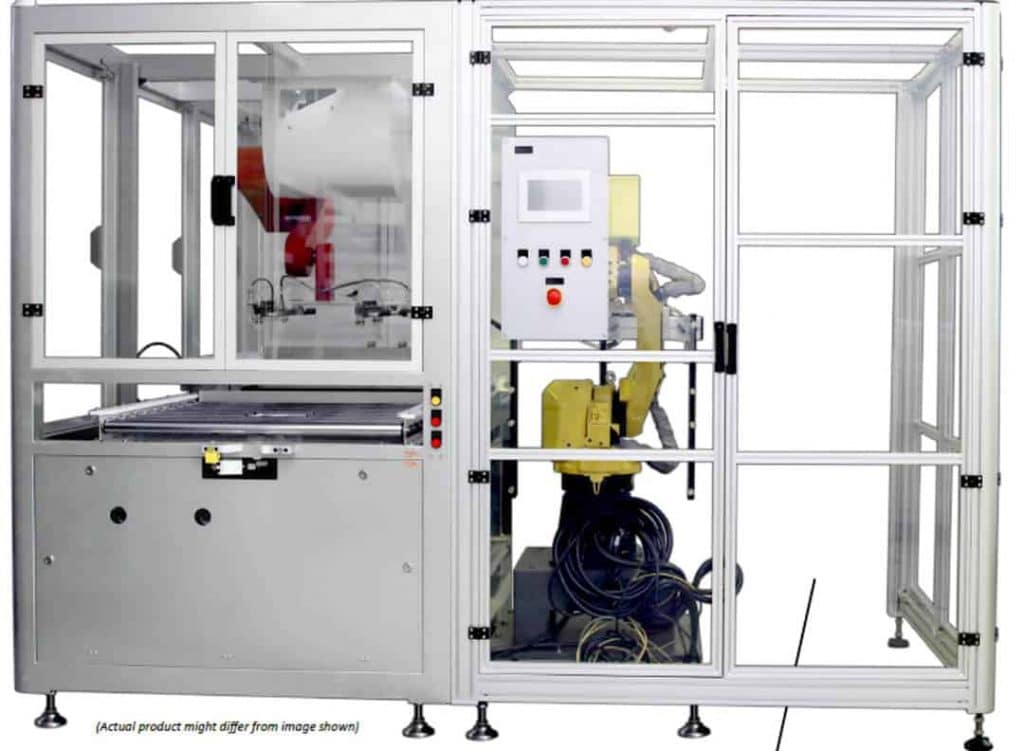

DI/LDI & AOI Automation ECOLINE

Highlights

- With a cycle time of approx. 20 sec/ PCB side, capacities of approx. 1.5 PCBs/min are possible

- Optional Automatic gripper adjustment with different PCB formats *

- Position on LDI/AOI table can be configured by +/- 90° or 180° (if necessary, cycle time savings for the process machine)

- Order data recording via DMC on the PCB or via job list

- Use of slip sheets*

- Alarm history

- Event history

Description

In a very compact design, thePCBs are fed inline, from inclined angle boxes or horizontal boxes via alignment table with integrated cleaning direction to the table of the process machine. The loading on the alignment station is carried out via a 3-axis robot. The transfer to the process machine is carried out via a 6-axis robot. By handing over the PCB from the 6-axis robot directly to the 3-axis robot after processing the first page, the turning takes place. If inclined angle cassettes or horizontal boxes are used, all A-sides are processed first and then all B-sides, so that the PCBs are discharged into the same cassette or box and in the same order as they were fed to the process. Slip sheetscan be used as an option.

Klicken Sie auf den unteren Button, um den Inhalt von customer-181znpukyiq9repm.cloudflarestream.com zu laden.