Highlights

- Customer- and plant-specific plant design

- Order data recording via DMC on the printed circuit board or via job list

- Automatic dummy handling

- Automatic format-dependent gripper adjustment (optional)

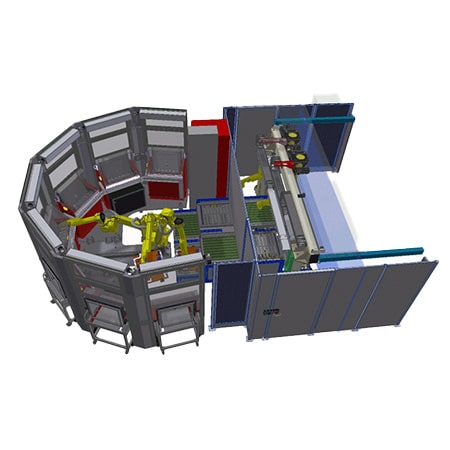

Description

The fully automatic loading and unloading of vertical electroplating automations is always a special challenge here. Special attention applies to the integration of customer- and plant-specific clamping contacts as well as the handling of the most diverse PCB specifications and sizes. 6-axis robot solutions ensure reliable and reproducible automation between goods carriers, reading the order data on the printed circuit boards, loading and unloading the electroplating racks and transferring the printed circuit boards back to the goods carriers. The order-specific use of dummy plates is taken into account as well as the automatic adaptation of the vacuum gripper systems to different plate formats.

Klicken Sie auf den unteren Button, um den Inhalt von customer-181znpukyiq9repm.cloudflarestream.com zu laden.