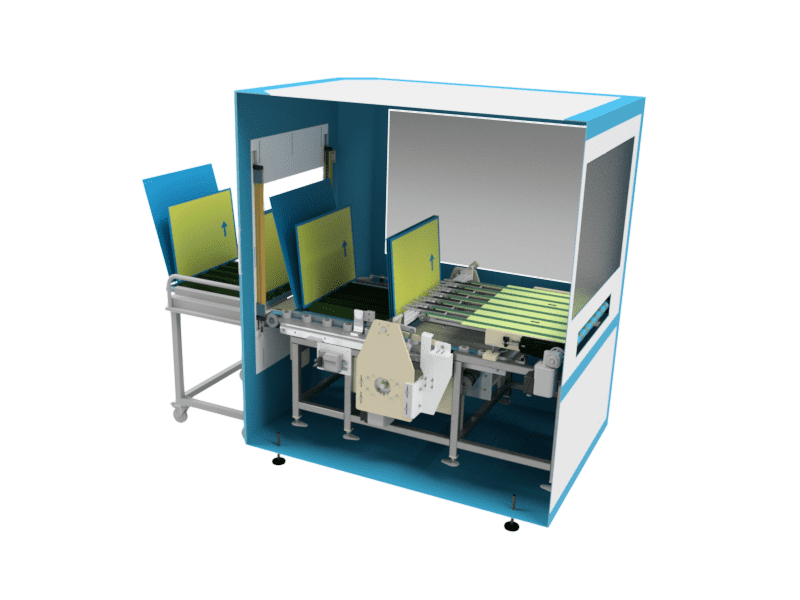

Slot-Cassette Automation SC

Kategorie:

Loader / unloader Solutions

Specially developed for loading and unloading of printed circuit boards in the Soldermask area.

Highlights

- Alarm and Event Logging

- Signal exchange to upstream and downstream process machines

- Capacity approx. 3-4 panels/min

- DMC Reader and job tracking*

- Interface to customer MES or databases*

- Slot-cassettes for different PCB thicknesses*

- Typ A: 0,8 – 2,2mm

- Typ B: 2,2 – 3,2mm

- Typ C: 3,2 – 4,8mm

*Optional

Description

The slot-cassettes are fed into the system via trolleys and are precisely positioned. In the loader the PCBs will then be clamped at the bottom edge, lifted out of the slots, turned, and placed on the loading transport. In the unloader the PCBs will be clamped in the end- position of the outfeed transport, turned, and placed down into the slots of the slot cassette. After each loading, respectively unloading cycle, the slot-cassette will automatically be moved forward respectively backwards by exactly one slot position. The slot-cassettes can be provided in diff erent slot-sizes according to the PCB thickness. Optionally the automation system can be equipped with automatic slot-cassette exchange- and -storage-stations.